Materials

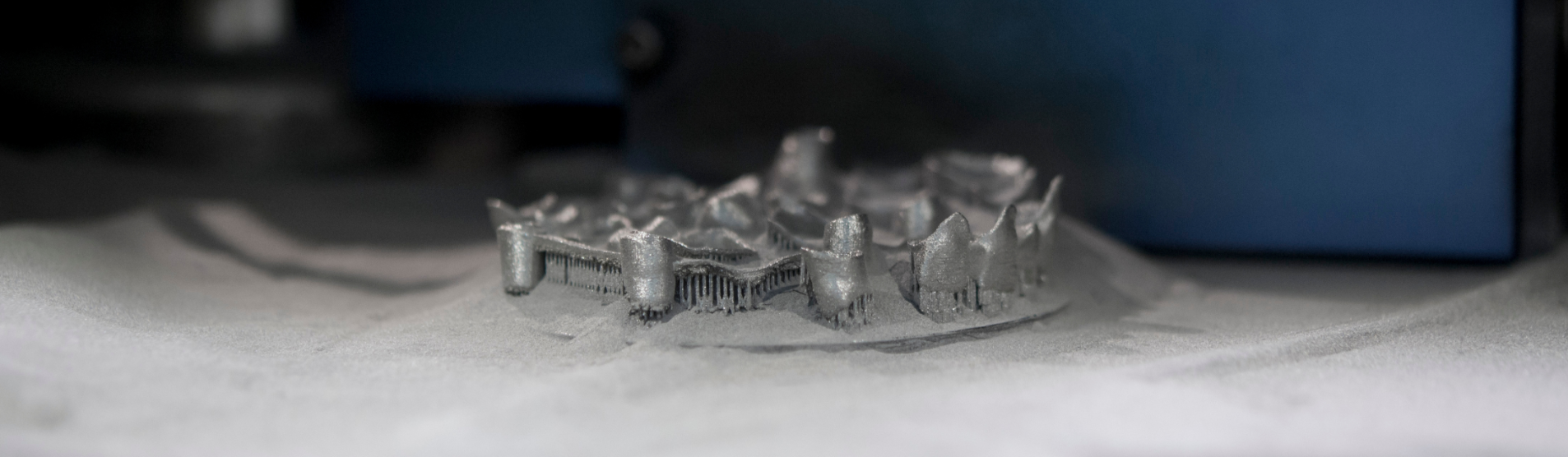

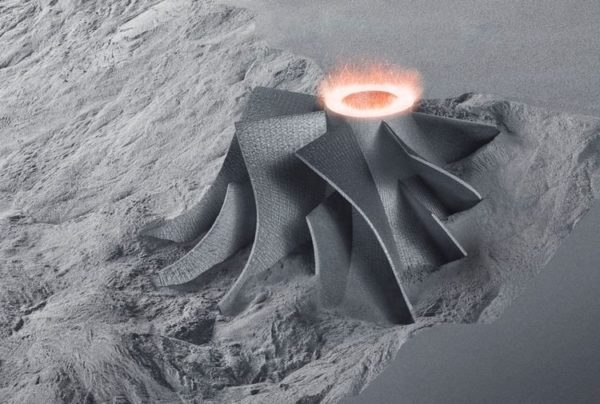

SLS Materials

Selective Laser Sintering (SLS) technology offers a high level of resolution, productivity and material availability; making it well-suited for various applications. This includes rapid prototyping, production of end-use parts with complex geometries and printing-in-place parts. This versatility allows designers and engineers to create complex structures and components quickly and efficiently, reducing the need for manual assembly and post-processing operations.

FDM Materials

Fused Deposition Modeling (FDM) is indeed one of the earliest additive manufacturing techniques, known for its versatility and accessibility. It employs a wide range of thermoplastic materials, allowing for customized material selection that caters to various applications. With a sizeable build volume of 300 x 300 x 600 mm, FDM can efficiently produce large parts, making it an ideal choice for both prototyping and production in industries such as aerospace, automotive, and consumer goods. This makes FDM a popular choice for manufacturers looking to leverage 3D printing technology for diverse projects.

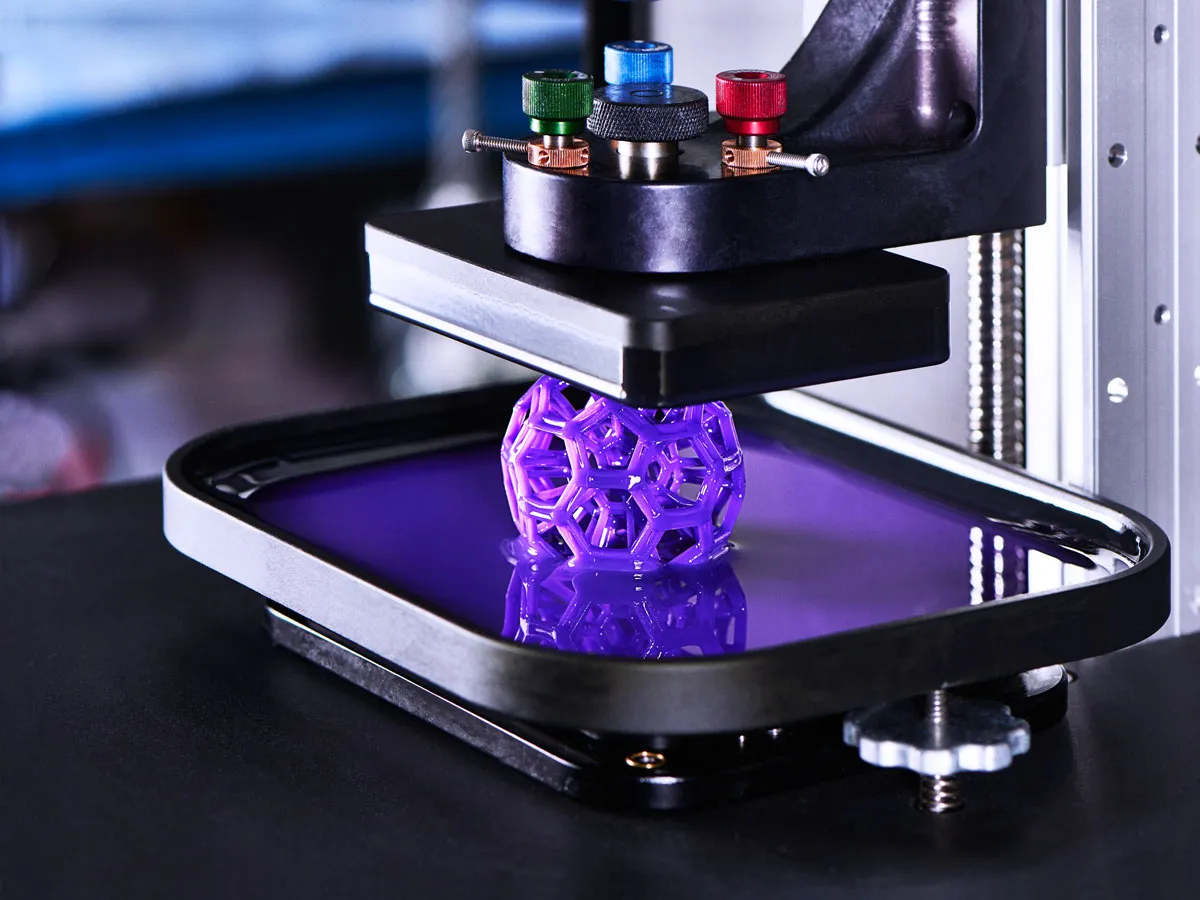

RESIN Materials

Digital Light Processing (DLP) and Stereolithography (SLA) are advanced 3D printing technologies that utilize photopolymers, which are liquid resins that cure into solid structures when exposed to UV light wavelengths. This allows for the creation of intricate geometries and fine details that are often difficult to achieve with traditional melted plastic methods. The ability to achieve smooth surface finishes is another advantage of these processes, making them ideal for applications in jewelry, dental, and prototyping industries where precision and aesthetics are crucial.